Unlock the Benefits of Automated Warehouse Systems

Chosen theme: Benefits of Automated Warehouse Systems. Join a practical, optimistic tour of automation’s real-world advantages—told through data, shop-floor stories, and actionable ideas you can apply today. Subscribe for fresh insights and share your bottlenecks so we can tackle them together.

Light-directed confirmations and barcode scans routinely push pick accuracy above ninety-nine point eight percent. That means fewer apology emails, fewer reships, and less hidden labor correcting errors. What is your current accuracy rate, and where do exceptions cluster most?

Accuracy Customers Can Feel

Automated weight checks and vision snapshots validate contents before sealing. If something looks off, the system escalates instantly, not after delivery. New hires ramp faster because visual cues make every step unambiguous, even across complex product assortments.

Accuracy Customers Can Feel

Ergonomics by Design

Goods-to-person stations bring items to waist height, cutting long walks and awkward reaches. A veteran picker told us her shoulders finally stopped aching after years of strain. What task tires your team most? Let’s redesign that motion together.

Risk Reduction

Fenced automation zones, speed‑limited AMRs, and automatic stop circuits reduce exposure to lift trucks and pinch points. Facilities report lower incident rates and smoother safety audits. Share your safety wins and we’ll highlight proven safeguards for similar workflows.

Upskilling Paths

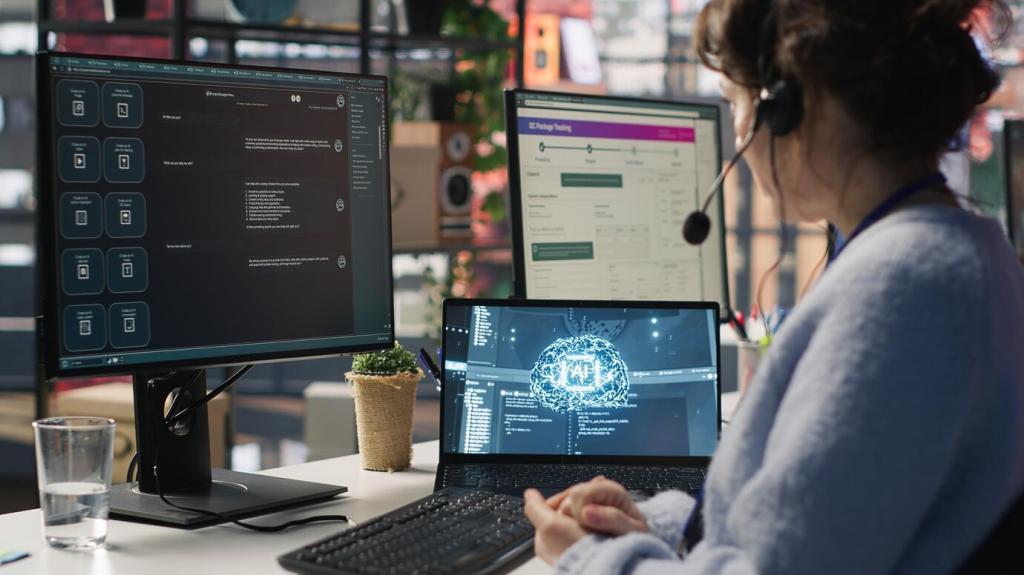

As robots handle travel, roles evolve toward maintenance techs, flow analysts, and data-driven leads. Create internal training ladders so people grow with the system. Subscribe for templates that turn today’s operators into tomorrow’s automation specialists.

Scalability and Space You Already Have

High-bay AS/RS and shuttle systems make use of cubic volume, often doubling effective storage without expanding the footprint. If your racks kiss the ceiling but aisles eat space, we’ll explore tighter, safer, and smarter vertical designs together.

Cost Savings That Compound

By blending labor with automation, facilities often see double‑digit cost-per-order reductions and paybacks in two to three years. Tell us your volume and SKU count, and we’ll propose a right‑sized path—not a one‑size promise.

Cost Savings That Compound

Regenerative drives, LED lighting, and zone‑activated conveyors cut kilowatt hours without slowing flow. Lower energy bills pair neatly with sustainability goals. Subscribe to receive a simple checklist for squeezing waste out of your current material handling.

Dashboards combine WMS, WES, and device telemetry into one clear picture: lines per hour, queue lengths, and aging orders. Mobile alerts prompt action before queues swell. Which three KPIs would your team watch every hour to stay ahead?

Sensors track vibration, temperature, and cycle counts to flag wear before failures. Planned micro-stops replace surprise downtime. Tell us which machine worries you most, and we’ll explore condition monitoring that fits your maintenance rhythm.

A/B test pick methods, batch sizes, or pack flows and watch the metrics move in real time. Digital twins let you trial changes safely. Subscribe to get case notes from teams turning tiny tweaks into outsized wins.